Explore our series

Do you want to uncover the mysteries of robotics in Škoda Auto? Or get to know our Talent program? You can find all of this and more in our ongoing article series.

Life in Škoda Auto

Be there when we come up with smart solutions. When we develop electromobility. When we make life easier for the people around us.

Select topic

- Benefits

- Connected car

- Corporate Social Responsibility

- Data analysis

- Blue-collar workers

- Designéři

- Digitization

- Diversity

- PhD Students

- Postgradual students

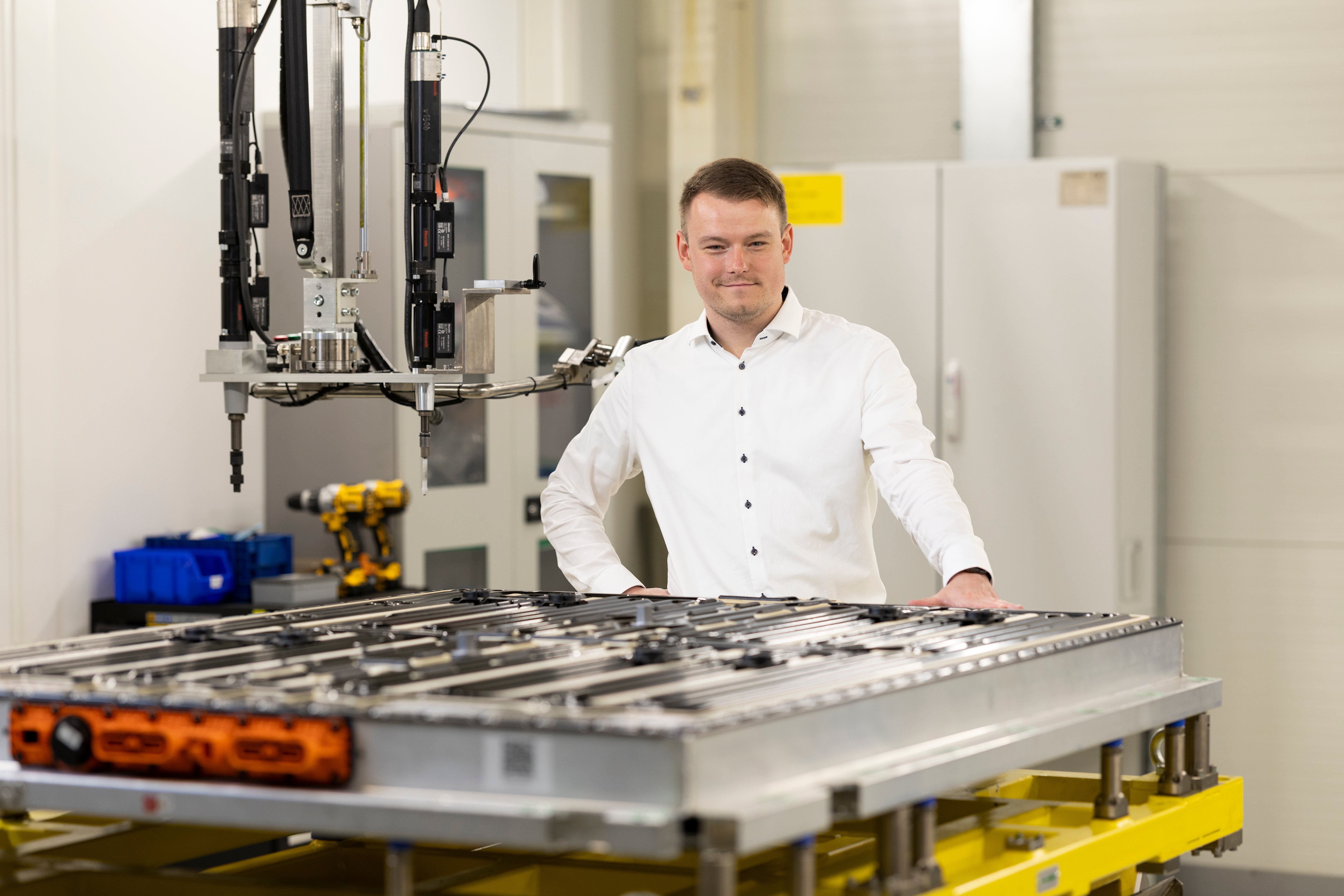

- Electromobility

- HR

- Innovation

- IT specialists

- IT

- Quality

- Logistics

- Graduates

- Analysts

- Marketers and economists

- Latest

- Care of employees

- Sales

- Project managers

- SAP

- Internships

- High schools

- 42 Prague

- Ergonomics

- Purchase

- Sustainability

- EA211

- Technical engeneer

- Other

- Trainee

- Students

- Trainee program

- Production

- Universities

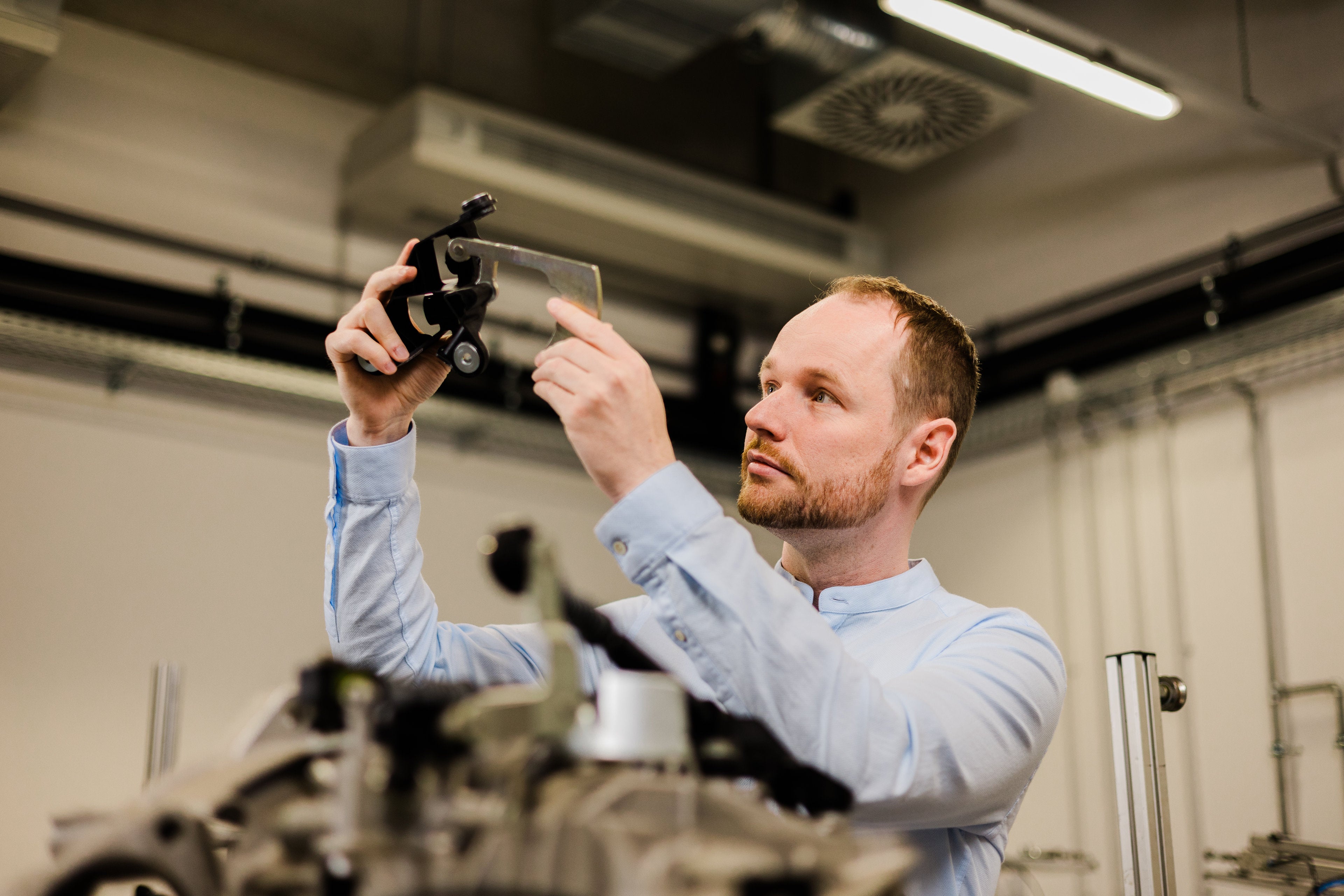

- Technical development

- Employee training

Select serial

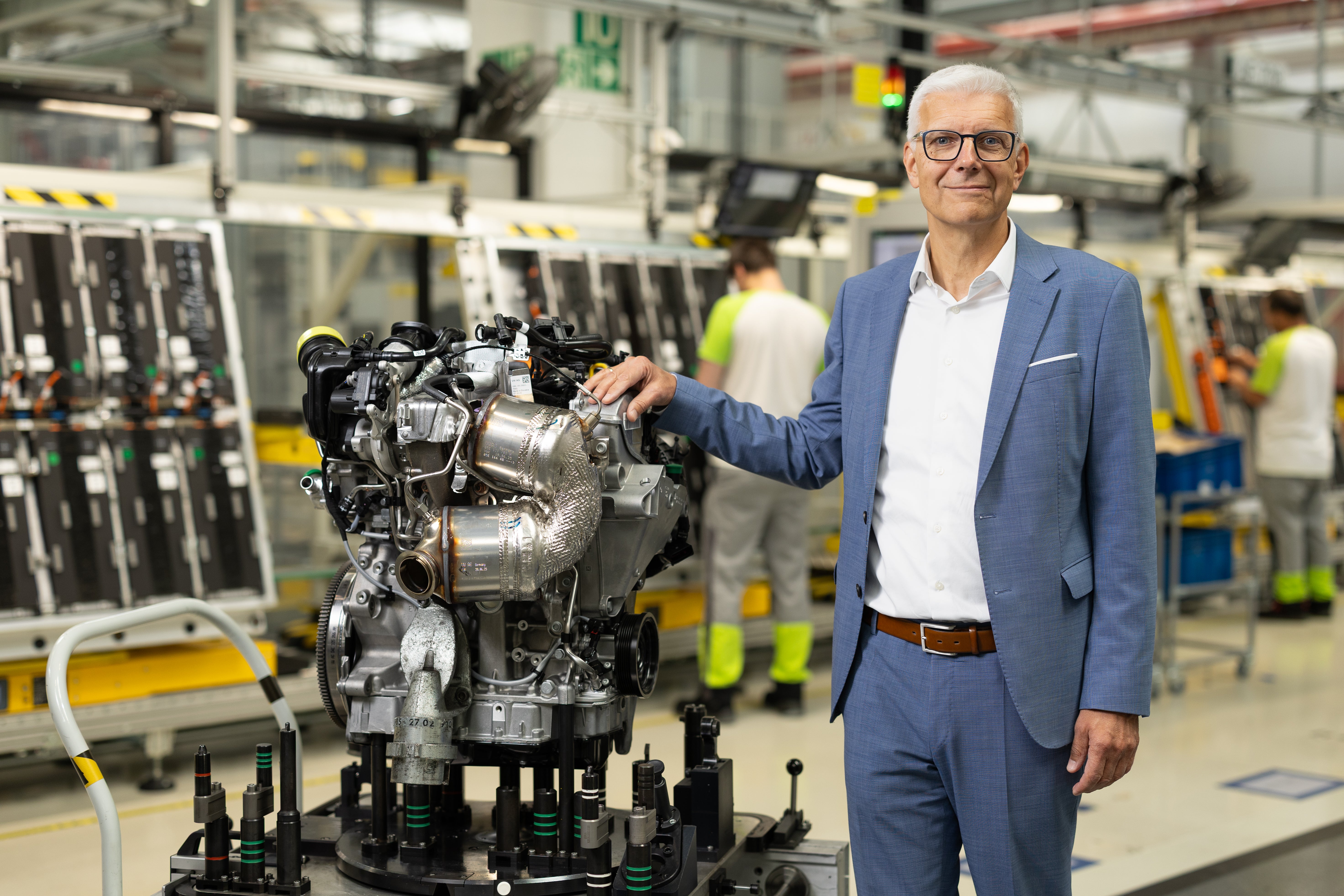

- The faces behind E211

- SAP Stories

- Written by Talents

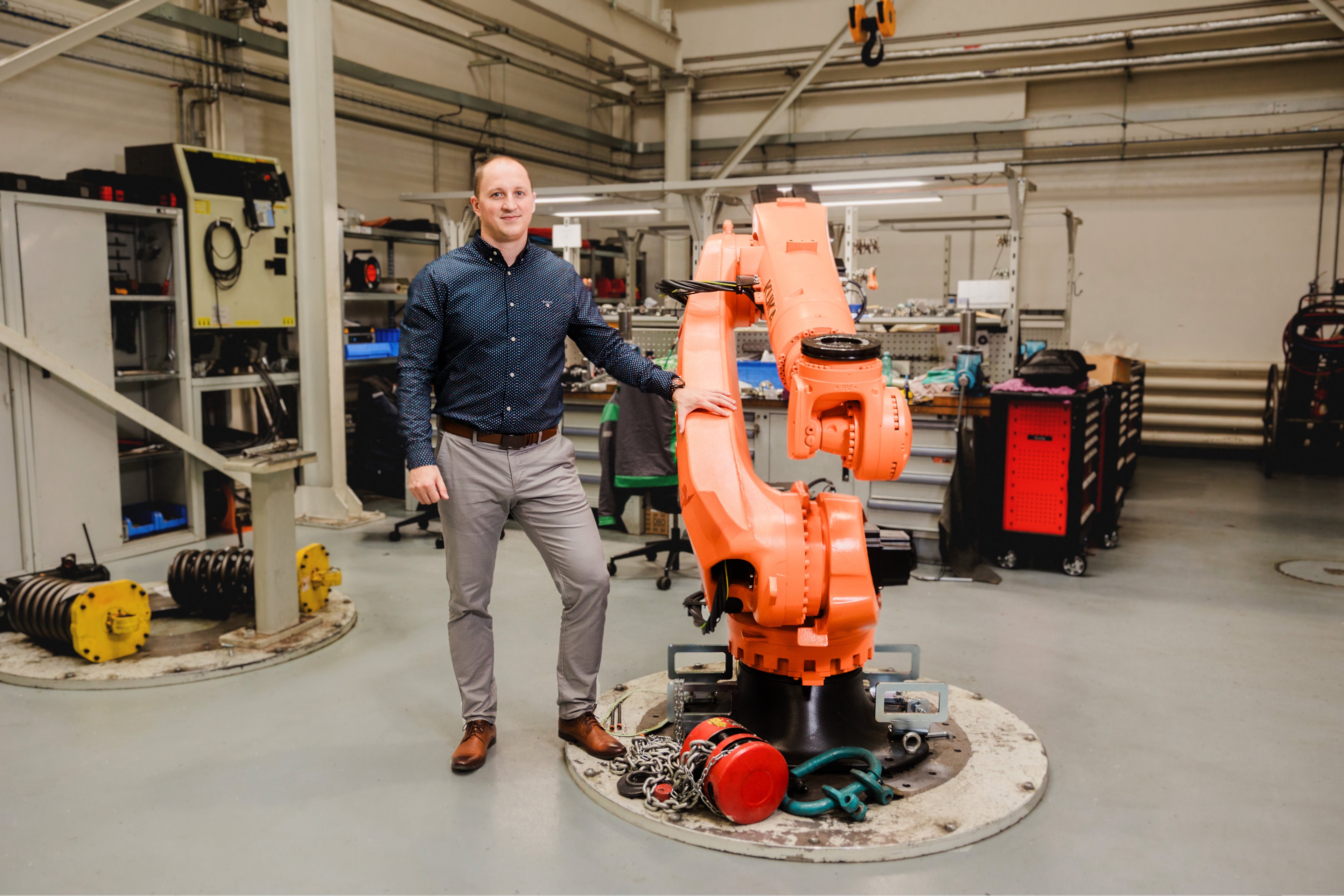

- Notes of robotics

Total found

277