From tool design to workforce planning and environmental measures — working in the brand management team brings together people, technologies, and strategies across the entire production process. Here, precision, efficiency, innovation, and responsibility for the environment come together. Whether you’re drawn to engineering, optimization, or methodical support, you’ll find your place with us.

Work on the design and production of tools for pressing, foundry, or welding operations, smart manufacturing, efficient energy use, or improving the quality of production processes.

What does Brand Management mean at Škoda Auto?

-

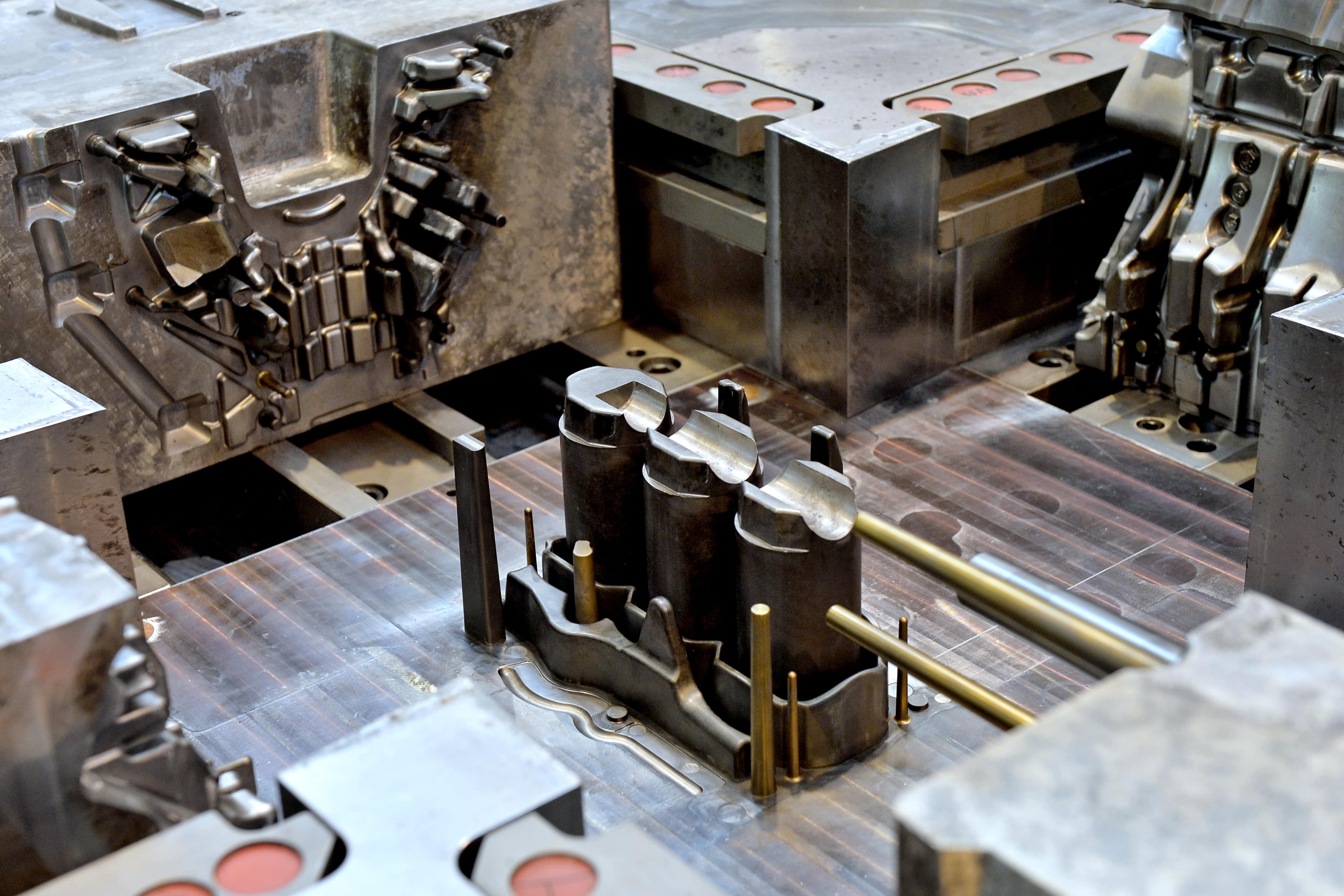

We manufacture pressing tools, welding jigs, and molds

Everything is prepared — from design and production to assembly and customer service.

-

Designing and optimizing

Our focus lies in planning workforce capacities according to production schedules, refining manufacturing processes and workplace ergonomics, training employees, and implementing Lean methods across production.

-

Shaping production strategy

Through the Peak program, we ensure that efficiency and simplicity are built into vehicle development from the very start. We also aim to expand automation and modularity while creating sustainable plants that deliver outstanding business results both in the Czech Republic and abroad.

-

Repairs, maintenance, and inspections

We take care of machinery and equipment maintenance across all plants, ensuring smooth and reliable operation.

-

Environmental protection, energy efficiency, and workplace safety

All preparations and processes at our facilities follow current legislation and reflect our commitment to sustainability and safety.

-

Driving innovation

Within our FabLab, we focus on applied research directly linked to vehicle manufacturing, developing solutions tailored to the needs of our production sites.

The impact of working in Brand Management

You see production through a different lens

You notice what others might overlook — how machines, people, systems, and energy all connect, and how decisions take shape in reality.

You create a solid framework for change

Change in production doesn’t happen by chance. It’s planned, deliberate, and precisely timed — and you’re the one who keeps it on course.

Your work stays behind the scenes — but it’s essential

It may not shine on billboards, yet without you, no tools would be made, no training would happen, and no innovations would emerge.

You influence more than you realize

From a single screw to long-term strategy — your imprint is visible in everything that happens in production, and even in what doesn’t, thanks to prevention.

You discover what responsible production looks like

Ecology, safety, efficiency — you learn to think of production as a living organism that breathes thanks to care and attention.

“I enjoy tackling technical challenges and finding new solutions. I don’t mind when a new approach means stepping out of my comfort zone.”

Construction Coordinator, Welding Tools and Fixtures Production

Where can you apply your skills?

Get to know the individual areas that shape the face of Brand Management.

1. Tool and Fixture Production

We build pressing, welding, and metallurgical tools, with a focus on automation. Our work covers anufacturability, design, and technological preparation, as well as assembly and servicing of tools — all while maintaining close communication with both internal and external customers.

2. Industrial Engineering

In serial production, we are responsible for planning workforce capacity according to the production schedule and for improving manufacturing processes to achieve maximum efficiency. We train employees in dedicated training centers and implement Lean methods across our production facilities. Our focus also includes enhancing workplace ergonomics and determining staffing needs for new model production. By monitoring competitors and analyzing productivity, we help shape the development of future vehicles.

3. Central Technical Service

We handle maintenance, reengineering, and repairs of machinery, while also coordinating and overseeing the upkeep of infrastructure, buildings, and green areas. Our team is responsible for Škoda Auto’s overall maintenance strategy, methodology, and internal technical standards. Within our FabLab innovation center, we identify and test new technologies, applying modern elements of predictive maintenance and artificial intelligence.

4. Ecology and Occupational Safety

We ensure compliance with legal requirements related to environmental protection and workplace safety. Our responsibilities include coordinating the company’s energy management system and overseeing compliance within the framework of environmental governance.

5. Production Strategy

We are responsible for the production strategy known as PEAK. Our team coordinates the Future Production Governance program (Preparing Production for the Future within the Volkswagen Group) for Central Europe and India. We oversee key activities within Brand Group Core and focus on optimizing processes in indirect areas of production and logistics. Additionally, we handle the coordination of risk management across the entire department.

“Every bit of energy we save has a positive impact on the environment. And when we do use energy, we should strive to remain as close to balance as possible.”

Head of Environmental and Occupational Safety Department

What can you look forward to at Škoda Auto?

Do the work you love, get fairly rewarded for it and enjoy plenty of extra perks.

Interesting figures from Brand Management

Energy savings per car since 2010.

Projects carried out for six Group brands (Škoda Auto, Porsche, Volkswagen DE and PL, Audi, Cupra) in 2025.

Employees trained in our training centers.

Who are we looking for?

Production Technician (m/f)

Are you looking for a technical challenge where you can see the results of your work every day?

Join the Škoda Auto team and be part of creating the cars of the future.

Your task will be to work with state-of-the-art technologies and take part in processes that push the boundaries of mobility. Expect innovation, opportunities for growth, and the stability of a trusted brand.

Become part of a team where your work truly makes a difference.

Internship in Production (m/f)

Are you looking for a meaningful internship that will move you forward? At Škoda Auto, you’ll join projects in production and logistics, where you’ll work with modern technologies like AI and 3D printing. You’ll gain valuable hands-on experience alongside experts who will guide you through your training. Expect a friendly environment, opportunities for growth, and a chance to see your work make a real impact on the future of mobility. No matter what year of study you’re in. What matters most is your curiosity, your drive to learn, and your passion for moving things forward!

Tech Trainee Program (m/f)

We’re looking for passionate talents from all technical fields – innovators, programmers, mechanical engineers, data analysts, electrical engineers, and more.

Over the course of one year, you’ll rotate through different technical areas and gain hands-on experience across the company. Discover cutting-edge technologies and be part of creating breakthrough innovations.

“We gain the necessary know-how through collaboration with Group partners and universities. In the future, we’d like to produce new components with specific properties.”

Project Coordinator for 3D Metal Printing