Precision to thousandths of a millimeter. Quality without compromise. Components that must last even a million kilometers – in freezing cold and scorching heat, at home and abroad. In the world of component production, everything revolves around absolute reliability.

At Škoda Auto, we produce engines, transmissions, axles, and castings for our own models as well as for the entire Group. In modern halls, with advanced automation and teams that understand every detail. Join us and bring millions more cars to life.

What does component manufacturing at Škoda Auto mean?

-

Production of key vehicle parts

Engines, transmissions, axles and battery systems are created directly in-house – we provide the heart and backbone of the vehicles.

-

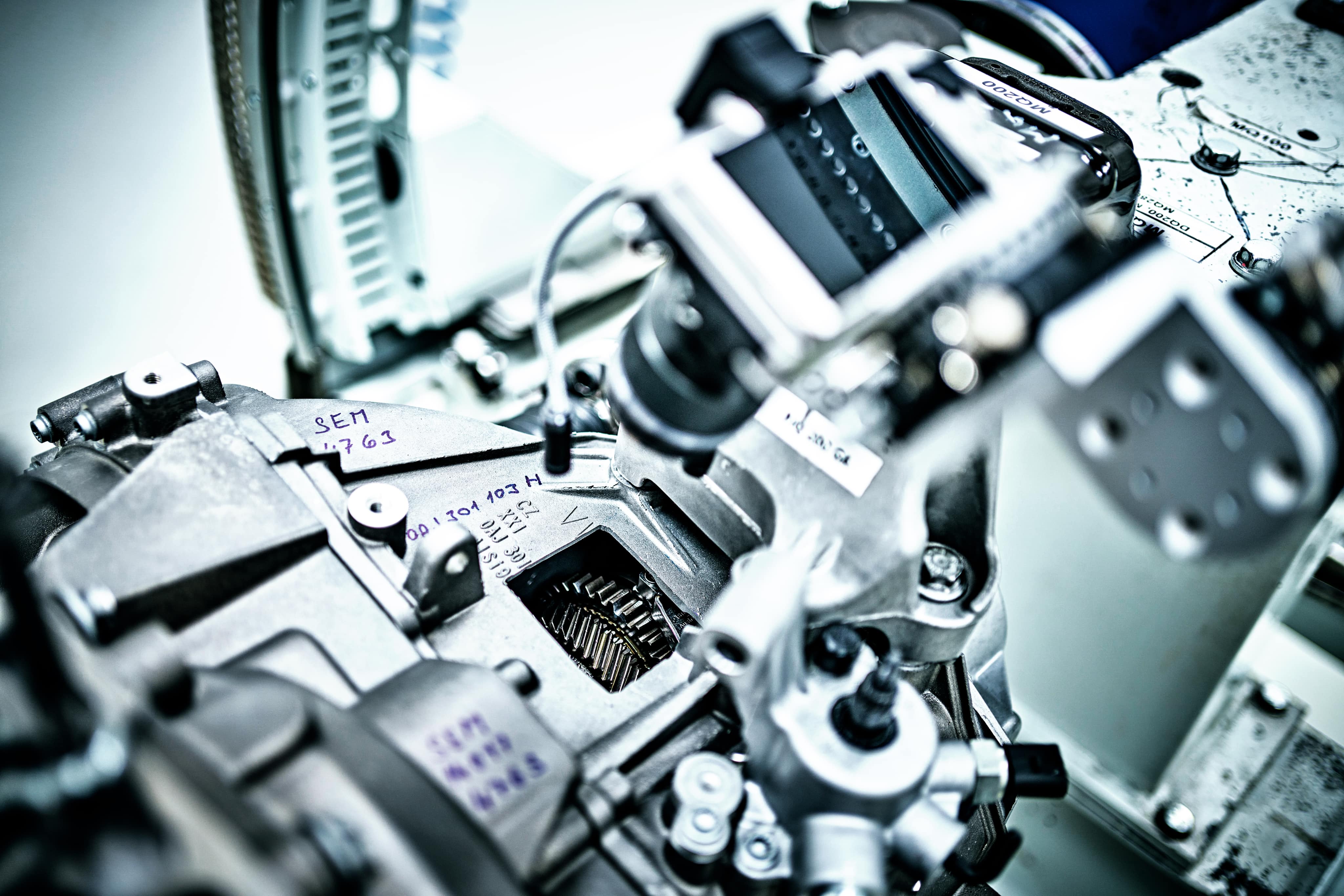

Precision machining with high accuracy

When producing engine blocks, connecting rods or crankshafts, we work with tolerances in the range of thousandths of a millimeter.

-

Assembly for the entire Group

Our components are used by the Škoda, Volkswagen, Audi and Seat brands – we assemble parts for the entire Group.

-

Production of castings and forgings

The foundry and forge ensure the melting and forging of parts that form the basis of power units.

-

Technical service and maintenance

We take care of tools, equipment maintenance and ensure the environmentally friendly operation of all technologies.

-

Component logistics

We keep planning, deliveries and material flow under control as part of comprehensive component logistics.

-

Ramp-up management of new component projects

-

Digitalization and smart production control

Automated data collection and modern control systems are moving our production toward a digital future.

“Every day, we produce over 2,000 engines and almost 4,000 transmissions. This production volume significantly contributes to the economic success of the Škoda Auto brand.”

Head of Component Production

Where can you apply your skills?

Get to know all the departments involved in producing components for Škoda vehicles.

1. Digitalization of component production

Implement smart control and automation systems. Coordinate digitalization projects, collect and evaluate data, and connect production with modern technologies.

2. Production of transmissions

Manufacture and ship automatic transmissions DQ200 (seven-speed automatic transmission with fast shifting) and manual transmissions MQ 200 (five- or six-speed manual transmission) for Škoda, VW, Audi and Seat vehicles. Take part in one of the most widely used drivetrains in the Group.

3. Engine production

Be part of the production of modern EA211 engines from the first machining step all the way to assembly. Work to the highest standards of quality and precision – down to thousandths of a millimeter.

4. Platform production

Produce batteries and axles for MEB vehicles, as well as damper units for the entire range of vehicles in Mladá Boleslav and Kvasiny. Under your hands, axles for hybrid vehicles and dampers for the Kodiaq iV will be created.

5. Foundry and forge

Melt, pour, and forge. Produce castings and forgings for the entire Group and gain experience in metallurgy, which forms the basis of all other processes.

6. Technical service for component production

Make sure production runs smoothly. Keep machines, tools, and technological processes in perfect condition and take part in environmentally responsible management.

7. Component production logistics

Plan and manage the flow of material and finished parts. Your work ensures that nothing is missing and that production runs exactly according to plan – at home and within the Group.

8. Project management and pre-series preparation

Launch new projects – especially in the field of e-mobility. Monitor costs, plan capacities, and coordinate the production of pre-series components.

About 10,000

axles and dampers per day.

That’s roughly how many parts are produced across our plants.

What can you look forward to at Škoda Auto?

Do the work you love, get fairly rewarded for it and enjoy plenty of extra perks.

“For hall M13, we produce front and rear axles and dampers – for more than 1,000 vehicles a day, which means over 3,000 components in current production.”

Production Management Coordinator

Who are we looking for?

Production Technician (m/f)

Are you looking for a technical challenge where you can see the results of your work every day?

Join the Škoda Auto team and be part of creating the cars of the future.

Your task will be to work with state-of-the-art technologies and take part in processes that push the boundaries of mobility. Expect innovation, opportunities for growth, and the stability of a trusted brand.

Become part of a team where your work truly makes a difference.

Internship in Production (m/f)

Are you looking for a meaningful internship that will move you forward? At Škoda Auto, you’ll join projects in production and logistics, where you’ll work with modern technologies like AI and 3D printing. You’ll gain valuable hands-on experience alongside experts who will guide you through your training. Expect a friendly environment, opportunities for growth, and a chance to see your work make a real impact on the future of mobility. No matter what year of study you’re in. What matters most is your curiosity, your drive to learn, and your passion for moving things forward!

Tech Trainee Program (m/f)

We’re looking for passionate talents from all technical fields – innovators, programmers, mechanical engineers, data analysts, electrical engineers, and more.

Over the course of one year, you’ll rotate through different technical areas and gain hands-on experience across the company. Discover cutting-edge technologies and be part of creating breakthrough innovations.

Number of employees in component production as of April 1, 2025:

employees in component production

How will working in component production impact you?

You give vehicles strength and confidence

Without an engine, a car wouldn’t move off, without a transmission it wouldn’t accelerate. Thanks to your work, every car really works.

You see the results every day

From machining machines, assembly lines and foundry molds. What you produce goes straight out into the world.

You get to know production in depth

Here you’ll understand how every part, every movement and every decision are connected. And also why it is important that everything fits to a thousandth exactly.

You work with modern technologies

Automation, robotics, digital systems – component production is smart, constantly evolving and offers plenty of room for learning and growth.

You are part of a well-coordinated team

Every day is different, but the team always sticks together and pulls as one for every single forging.

automatic DQ200 transmissions

EA211 engines

MEB batteries

million axles

manual MQ100/200 transmissions